Plant

-

1. Environmentally-Friendly Biomass Power Generation SystemBiomass power generation systems use wood chips (chips of wood) or wood pallets (compressed pallets of wood) as the fuel for the boiler to produce steam and electricity, reducing carbon and fine dust compared to the existing coal power plants and contributing to the fuel diversification of power stations in South Korea. Poseung Biomass Power Station, which generates about 43MW of electricity, was completed in Pyeongtaek, Gyeonggi-do, in 2018. Also, another power station project is currently in progress, to build a TW biomass power plant of a 25MW capacity in Yeosu. (To be completed by 2026.)

-

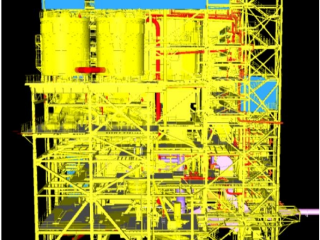

CFBC Boiler (Circulating Fluidized Bed Combustion Boiler)In this type of boiler, the fuel (woodchips or pallets) and fluidized sand circulate the inside of the boiler as heat media to deliver the heat. Compared to the existing powdered coal boilers, this type reduces pollutants and supports the use of various types of fuels, which are the advantages of this technology.

CFBC Boiler (Circulating Fluidized Bed Combustion Boiler)In this type of boiler, the fuel (woodchips or pallets) and fluidized sand circulate the inside of the boiler as heat media to deliver the heat. Compared to the existing powdered coal boilers, this type reduces pollutants and supports the use of various types of fuels, which are the advantages of this technology.- Reference projects: Poseung Biomass, TW Biomass

-

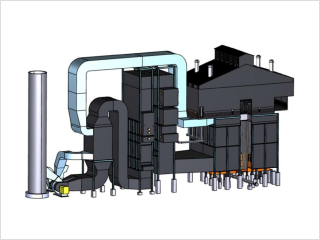

Flue Gas Treatment SystemWe applied a system that purifies pollutants within flue gases, such as sulfates, nitrogen oxides, dioxin, etc. using slaked lime, sodium hydrogen carbonate, and ammonium hydroxide. Especially, the TW Biomass Power Station is equipped with one of the best CDS system in the world.

Flue Gas Treatment SystemWe applied a system that purifies pollutants within flue gases, such as sulfates, nitrogen oxides, dioxin, etc. using slaked lime, sodium hydrogen carbonate, and ammonium hydroxide. Especially, the TW Biomass Power Station is equipped with one of the best CDS system in the world.- Reference projects: Poseung Biomass, TW Biomass

-

-

2. Carbon Neutral Conversion Solutions for Power StationsWe can simulate the changes in key performance indicators of a power station and analyze the economy of using ammonia or hydrogen instead of traditional fossil fuels or adding CCU equipment (carbon capture equipment) to existing power plants. Also, with this technology, we can identify the optimal carbon reduction solutions that we could propose to the business owner.

-

Ammonia crackingIf the hydrogen that is to fuel the power station is transported as ammonia, there needs to be a separate cracking facility not far from the power station. We have the capability to engineer an optimal system of equipment by analyzing the economy of each licensor technology that we can design, procure, and construct (EPC).

Ammonia crackingIf the hydrogen that is to fuel the power station is transported as ammonia, there needs to be a separate cracking facility not far from the power station. We have the capability to engineer an optimal system of equipment by analyzing the economy of each licensor technology that we can design, procure, and construct (EPC). -

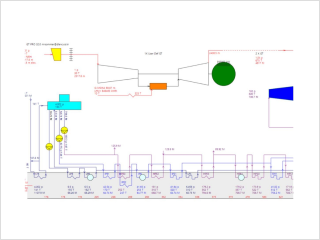

Analysis of the performance when using hydrogen/ammonia fuelWhen hydrogen or ammonia fuels are mixed in traditional power stations, the output and efficiency of the power station will change. The performance of the power station is one of the most influential factors of equipment operation cost and economy. Therefore, it is very important to estimate the changes in performance in advance. We have the capability to use our simulation technology to estimate the changes in performance when the station shifts to a new fuel and analyze its economy.

Analysis of the performance when using hydrogen/ammonia fuelWhen hydrogen or ammonia fuels are mixed in traditional power stations, the output and efficiency of the power station will change. The performance of the power station is one of the most influential factors of equipment operation cost and economy. Therefore, it is very important to estimate the changes in performance in advance. We have the capability to use our simulation technology to estimate the changes in performance when the station shifts to a new fuel and analyze its economy. -

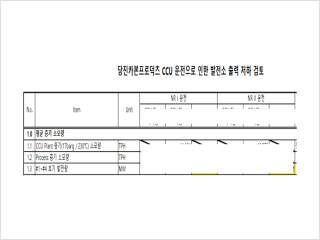

Performance analysis of CCUS FacilitiesIf CCU equipment is added to an existing power station, the performance of the power station will change, due to the changes in the pressure of exhaust gases, the output within the station, and the changes in the amount of steam used. To analyze the economy, it is essential to estimate the changes in the performance of the power station due to the use of CCU equipment. We have the capability to carry out such simulations on our own.

Performance analysis of CCUS FacilitiesIf CCU equipment is added to an existing power station, the performance of the power station will change, due to the changes in the pressure of exhaust gases, the output within the station, and the changes in the amount of steam used. To analyze the economy, it is essential to estimate the changes in the performance of the power station due to the use of CCU equipment. We have the capability to carry out such simulations on our own.- Bidding: Dangjin Carbon Products CCU, SWCC CCUS (Saudi Arabia)

-