Civil engineering

-

1. Dam Building TechnologyA dam is constructed to contain water, which is again to secure water resources and control floods. Since it is a large-scale structure, it is necessary to develop technologies that are economical and capable of enhancing efficiency in terms of space and water containment. For this reason, we have developed the compound dam construction technology that combines the strengths of different dam construction methods, in addition to an efficient core-zone formation technology and mobile water containment structure, etc.

-

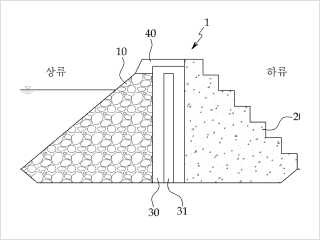

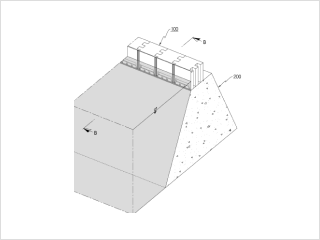

Compound dam construction methodThe upstream part is composed of a fill zone, which is constructed with sand, gravel, rocks, and soil, while the downstream part is a concrete zone built with concrete. These two different types of dams are joined by this technology into a single, integrated dam structure.

Compound dam construction methodThe upstream part is composed of a fill zone, which is constructed with sand, gravel, rocks, and soil, while the downstream part is a concrete zone built with concrete. These two different types of dams are joined by this technology into a single, integrated dam structure.- Intellectual property right: Registered Patent 10-1739657

-

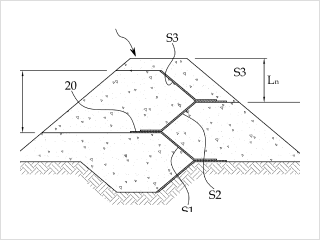

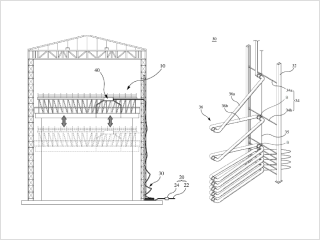

Core-type rock-fill dam construction methodThis technology is used to make a dam stronger and more efficient. While the traditional method places a separate waterproof zone in the middle of the dam, this method installs waterproofing sheets in a zigzag pattern while piling and compacting soil. The waterproofing sheet on each floor is heated to completely bond with the structure, which reduces the time taken in construction and makes it possible to build a strong dam that is definitely waterproof.

Core-type rock-fill dam construction methodThis technology is used to make a dam stronger and more efficient. While the traditional method places a separate waterproof zone in the middle of the dam, this method installs waterproofing sheets in a zigzag pattern while piling and compacting soil. The waterproofing sheet on each floor is heated to completely bond with the structure, which reduces the time taken in construction and makes it possible to build a strong dam that is definitely waterproof.- Intellectual property right: Registered patent 10-1739699

-

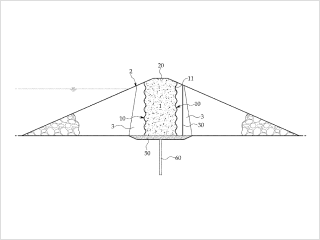

Asphalt core-fill damThis is a novel method of waterproofing the core of a dam in a more effective manner. Specially designed waterproofing materials of wavy forms are installed to prevent water from permeating into the structure, while reinforcing the surrounding area with low-strength concrete. Such a wavy structure is more resistant to water pressure while providing a better waterproofing performance.

Asphalt core-fill damThis is a novel method of waterproofing the core of a dam in a more effective manner. Specially designed waterproofing materials of wavy forms are installed to prevent water from permeating into the structure, while reinforcing the surrounding area with low-strength concrete. Such a wavy structure is more resistant to water pressure while providing a better waterproofing performance.- Intellectual property right: Registered Patent 10-1570939

-

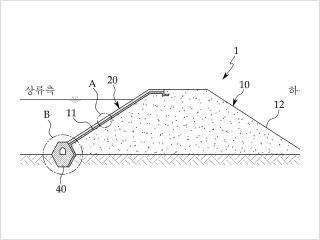

Surface water containment damThis technology dramatically improves the waterproofing performance of the surface of a dam. The surface of the soil dam structure is covered with a layer of special waterproofing sheet, which is again coated with concrete mats to provide dual protection. Such dual protective layers are easy to build and prevent damage due to water pressure, making the dams much safer.

Surface water containment damThis technology dramatically improves the waterproofing performance of the surface of a dam. The surface of the soil dam structure is covered with a layer of special waterproofing sheet, which is again coated with concrete mats to provide dual protection. Such dual protective layers are easy to build and prevent damage due to water pressure, making the dams much safer.- Intellectual property right: Registered Patent 10-1758023

-

Independent mobile water containment structureThis mobile dam construction technology effectively contains the water at the construction site. A special box-formed member is assembled to construct this structure. The inside of the box is filled with water to increase its weight, and this ensures the stability of the structure without separate supports. The primary advantage of this method is that it is easier to build a height and to remove after the construction, to be moved to another construction site and reused.

Independent mobile water containment structureThis mobile dam construction technology effectively contains the water at the construction site. A special box-formed member is assembled to construct this structure. The inside of the box is filled with water to increase its weight, and this ensures the stability of the structure without separate supports. The primary advantage of this method is that it is easier to build a height and to remove after the construction, to be moved to another construction site and reused.- Intellectual property right: Registered Patent 10-1816832

-

-

2. Caisson concrete casting technologyThis technology is an improved version of the gantry slipforming technique that is used when building large-scale harbor structures. While the construction took more time due to the difficulties in concrete supply and the low proficiency of workers, our new concrete feeding mechanism increased the speed of concrete supply significantly without using additional equipment, making the construction work much faster and more efficient.

-

Caisson gantry slipform concrete feederThis equipment supplies concrete continuously to molds when building harbor structures. The machine moves along the mobile mold (slipform) automatically to deliver the concrete that is fed in from outside where it is needed precisely. Especially, it is possible to provide concrete in a stabilized manner even when the slipform moves up and down, increasing construction quality and speed significantly.

Caisson gantry slipform concrete feederThis equipment supplies concrete continuously to molds when building harbor structures. The machine moves along the mobile mold (slipform) automatically to deliver the concrete that is fed in from outside where it is needed precisely. Especially, it is possible to provide concrete in a stabilized manner even when the slipform moves up and down, increasing construction quality and speed significantly.- Intellectual property right: Registered Patent 10-2583840

-

-

3. Wave Power Generation SystemThis technology utilizes the energy of incoming waves by converting it to the driving force for turbines or other driving mechanisms. It is capable of generating energy indefinitely while emitting no greenhouse gases. It can be a valid alternative for island areas where it is difficult to establish large-scale power stations due to smaller demands despite the difficulties in power distribution and supply.

-

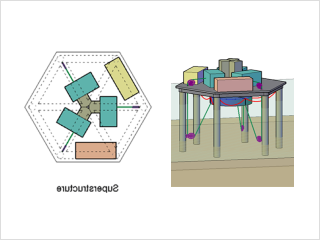

Integrated marine platform floating wave power generation systemThis technology, which generates power in an efficient manner on the sea, converts all wave movements into electric energy by connecting the power generators on the top and the floater at the bottom using short power generation ropes. As there is no need to drive piles on the sea bottom for fixing the equipment unlike traditional facilities, the construction cost is significantly reduced, while power generation efficiency is even higher.

Integrated marine platform floating wave power generation systemThis technology, which generates power in an efficient manner on the sea, converts all wave movements into electric energy by connecting the power generators on the top and the floater at the bottom using short power generation ropes. As there is no need to drive piles on the sea bottom for fixing the equipment unlike traditional facilities, the construction cost is significantly reduced, while power generation efficiency is even higher.- Intellectual property right: Registered Patent 10-2682918

-