HOME

Bridge Technology & Consulting

The pioneer in bridge construction, we make dreams come true.

DL E&C establishes a total solution to bridges by developing the bridge technology optimized in terms of constructability and economic feasibility, conducting construction engineering etc.

Technologies Owned

Suspension Bridge Equipment and Construction Engineering R&D

- Development of suspension bridge cable construction equipment

- Suspension bridge cable analysis and design

- Development of temporary facility design program of suspension

bridge cables - Installation of atypical suspension bridge cables

- Development of reinforcement equipment of suspension bridge

- Development of atypical suspension bridge reinforcement girders

Concrete Cable-Stayed Bridge R&D

- Configuration management

- Wind resistance evaluation during construction

- Means to review cracks and optimal operation of F/T

- Curved tower construction

- IT-based cable tension measurement

- Saddle-type settlement cable installation

Concrete Materials R&D

- Mass concrete temperature crack control

- Concrete strength revelation control

- (Special) concrete mix design

- Concrete hydration reaction analysis and evaluation

- Marine concrete durability analysis and evaluation

- Concrete safety diagnosis and evaluation

- Concrete self-compacting and non-compaction

BIM (Building Information Modeling) R&D

- Linkage of 3D object-based cost with schedule information

- 3D object-based information management

- 3D modeling-based automatic output calculation

- Technology linking mobile-based structure 3D modeling and EVMS

- Mobile and 3D modeling-based real-time process management

- Construction simulation

Representative Technologies

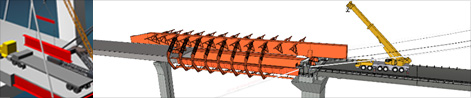

Suspension Bridge Construction Equipment and Engineering

Technology

overview

- We developed and applied main cable installation and cable reinforcement technologies ― the core factor technologies for suspension bridge ― to secure the independence of suspension bridge construction technology. With the development of the technology, we consolidate our competitiveness in the global suspension bridge construction market through leading domestic suspension bridge technology and by advancing our technological capabilities comparable to those of global top-class companies.

Effects

- Cost savings and buildability improvement

Applied projects

- Korea’s longest suspension bridge, Yi Sun-Sin Bridge: main cable air spinning, cable configuration management, and reinforcement technologies

- Korea’s first short span suspension bridge, Palyoung Bridge: main cable air spinning, cable configuration management, and reinforcement technologies

- World’s longest 1-tower suspension bridge, Gogunsan Bridge: main cable air spinning, reinforcement construction, and 3D cable configuration management

- Korea’s first 3-tower suspension bridge, Cheonsa Bridge: main cable PPWS construction and 3-tower suspension bridge reinforcement technologies

- World’s longest suspension bridge, 1915 Çanakkale Bridge: steel tower construction and configuration management

Intellectual

Property Rights

- Patent No. 10-1159449: catwalk rope carrier using the friction of hauling cables

- Patent No. 10-1210123: vertical wire sheave that can be rotated horizontally

- Patent No. 10-1213317: driving winch with two shafts for high speed and low speed for the construction of suspension bridge cables

- Patent No. 10-1190338: installation method and apparatus for catwalk ropes in suspension bridge by controlling the tension force of the catwalk rope

- Patent No. 10-1159450: installation method for catwalk rope in suspension bridge by passing the catwalk rope carrier through guide rollers at a pylon under condition of tensile force relaxation in catwalk rope

- Patent No. 10-1349298: crane apparatus for suspension bridge and method of elevating bridge block for suspension bridge

- Patent No. 10-1655332: suspension bridge with coupling reinforcing cables for the main cable and construction method thereof

- Patent No. 10-2004961: lifting gantry with cable deviation warning and prevention structure

Concrete Cable-Stayed Bridge Construction Technology

Technology

overview

- Cable-stayed bridges are actively applied to inland road construction as well as land-connecting bridges as economical and aesthetic design is possible. We have built up cable-stayed bridge construction technologies through Samcheonpo Bridge and Cheongpung Bridge, starting with Seohae Bridge. We have built differentiated construction engineering (CE) service systems by obtaining the core technologies required for concrete cable-stayed bridge construction, which replaced the existing reinforcement material with concrete. In this way, DL E&C plays a leading role in the industry by applying the technologies in domestic and international markets.

Effects

- Cost savings and buildability and quality improvement

Applied projects

- Korea’s first marine concrete cable-stayed bridge, Turtle Ship Bridge: configuration management, wind resistance stability evaluation during construction, FT optimum operation technologies

- Korea’s first curved cable-stayed bridge, Sepung Bridge: configuration management, F/T optimum operation technologies

- Koreas’ first curved slanted tower cable-stayed bridge, Handuri Bridge: curved tower construction technology

- Brunei’s first cable-stayed bridge, Riphas Bridge: configuration management technology and F/T optimum operation technology

- Brunei’s longest cable-stayed bridge, Temburong Bridge: saddle-type settlement cable, fire resistance cable design and construction, and 3D curved tower construction technologies

Intellectual

Property Rights

- Patent No. 10-1326726: tensile stress apparatus and method in tension member with fiber bragg grating sensor

- Program No. C-2012-010773: load cell indication program

- Patent No. 10-2064969: waterproof seal structure between PC house and pile and period-specific construction method thereof

- Patent No. 10-1646027: waterproof seal structure between PC house and pile and construction method thereof

Low price high-performance concrete

Technology

overview

- Low price high-performance concrete technology utilizing low cost eco-friendly materials

Effects

- Enhances concrete durability (durability period) of a marine bridge, reduces the strength development period(construction period), controls harbor caisson concrete hydration heat, and improves construction speed

Applied projects

- Singapore TTP1 construction site, Busan New Port, Angol Bridge, etc.

Intellectual

Property Rights

- Patent No. 10-2013-0130489 : Regarding high-durability concrete utilizing blast-furnace slag

Concrete Self-Compacting and Non-Compaction Technology

Technology

overview

- Unlike existing self-compacting concrete requiring lots of cement bonding materials, we developed low-cement self-compacting concrete compacted by flowing like water using a small amount of cement as well as non-compacting construction technology

Effects

- Expansion of application subjects, cost savings, buildability improvement, and defect risk reduction

Applied projects

- Saemangeum South-North Road Section 3, Milyang-Ulsan Expressway Section 7, Yeongam-Haenam Access Road Section 1, Chungju Dam water amount control capacity increase, Songsan-Sihwa connection road

Intellectual

Property Rights

- Patent No. 10-1985774: self-compacting concrete composition containing flowable admixture

- Patent No. 10-199223: self-compacting additive composition for concrete and low strength self-compacting concrete structure using the same composition

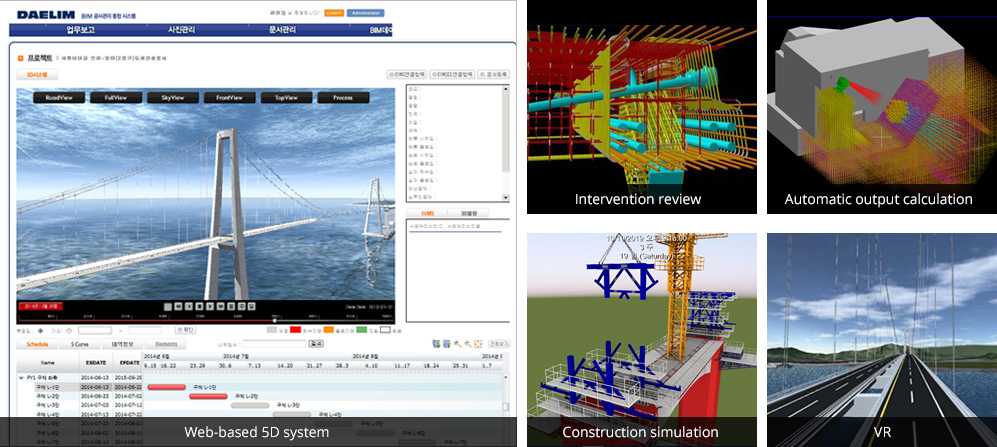

BIM (Building Information Modeling)

Technology

overview

- BIM technology in the civil engineering works sector enables checking in real-time the visual process and cost through the linkage of 3D model with the existing EVMS (earned value management system). The BIM technology contributes to productivity improvement and smooth communication between construction sites and head office by rationally improving the construction management process with a review of interventions between members in advance. We aim to lead the civil works BIM market by presenting the national civil engineering works’ BIM standard model.

Effects

- Construction period reduction and buildability improvement

Applied projects

- 3D object-based EVMS: Handuri Bridge and Cheonsa Bridge

- 3D object-based process management system: Seonam Environmental Technology and Sihwa Construction Section 3

- Intervention review and output calculation: Cheongpung Bridge, Jeokgeum Bridge, Palyoung Bridge, Simgok 2 Bridge, Turtle Ship Bridge and many others

Intellectual

Property Rights

- Patent No. 10-1263655: building information modeling system for cost and schedule management and operation method thereof

- Program No. S-2010-002952: 3D object-based cost and schedule integrated management system